Box build

understanding all aspects

What is box build?

Electronic assemblies are in high demand. Almost no matter where you look, you will see a box build devise. Your mobile phone or laptop you are reading this article on, and the headphones you are listening to podcast through. But also more elaborate devises in the industry often contain a box build.

Electronic assemblies are in high demand. Almost no matter where you look, you will see a box build devise. Your mobile phone or laptop you are reading this article on, and the headphones you are listening to podcast through. But also more elaborate devises in the industry often contain a box build.

In this article you will learn all about box build assembly. We will delve into the depths of box build assembly, unravelling its significance, difficulties, and advantages. We will navigate through the complexities of this pivotal manufacturing stage, exploring how outsourcing to an external provider can reinforce your production process.

Read the full article or go through the table of content to find the exact chapter you need.

- What defines box build assembly?

- What is a box build used for and where?

- Examples of a box build

- What are the difficulties in box build assembly?

- What are the relevant quality certificates?

- Who offers box build assembly?

- What are the advantages of outsourcing your box build assembly?

- Box build assembly – a complicated process

A box build can be defined as an enclosure of electronics. They are often customised to the needs of the user, and have different levels of complexity, depending on the customer and their requirements for the product.

Box build assembly consist of both design, production, and construction.

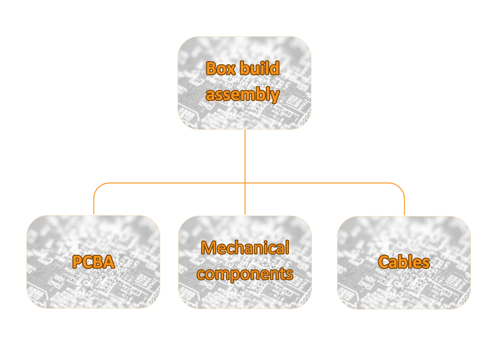

In short, box build consists of 3 elements: printed circuit board assembly (PCBA), mechanical components, and cables. Every part - from component to assembly - of the product is most often customer-based, meaning that the box build is assembled according to drawings and instructions from the customer.

Printed circuit board assembly (PCBA)

PCBA is a fundamental process in electronics manufacturing. This part is what connects all the electric components and mechanically support the box build. The PCB assembly involves assembling various electronic components onto a printed circuit board to create functional devices.

These components, including microchips, resistors, capacitors, and connectors, are carefully placed and soldered onto the board using advanced machinery and skilled labour.

PCBA is a critical step in the production of the box build, as it determines the device's functionality and performance. The precise arrangement and secure soldering of components ensure proper electrical connections, signal integrity, and overall reliability.

PCBA combines design, engineering, and manufacturing expertise. The efficiency and accuracy of the PCBA process significantly impact the quality and functionality of the final product, making it an essential aspect of box build assembly and modern electronics production.

Read about the PCB assembly process, components, and challenges here.

Mechanical components

The enclosure is a key mechanical component in a box build assembly, serving as the protective shell that houses and shields the internal electronic components. Designed with precision, the enclosure ensures both functional integrity and physical protection for the box build.

Manufactured from durable materials such as metal or high-quality plastics, the enclosure provides robust defence against environmental factors, physical stress, and potential electromagnetic interference. Its design factors in ventilation and heat dissipation to maintain optimal operating conditions for the enclosed electronics.

Beyond safeguarding the internal components, the enclosure often includes openings for input/output interfaces, buttons, displays, and connectors. These allow users to interact with the device seamlessly.

Its aesthetic design can also play a role in the product's overall appeal, aligning with company branding and user preferences.

Cables

The cables are carefully designed to meet the requirements of the box build regarding data transmitting, signals, and electricity. They play a critical role in the functionality and operation of the assembly.

Watch this video about cable assembly and quality control.

Cables are meticulously selected based on factors such as data transfer speed, power requirements, and environmental conditions. They are often shielded or insulated to prevent interference, ensuring optimal signal quality.

Whether transmitting information between circuit boards, connecting peripheral devices, or supplying power to various modules, cables are the element that keeps the components working in harmony.

A prober arrangement and management of cables within the box build also contribute to the device's overall efficiency and aesthetics. Efficient cable routing minimises clutter, enhances airflow for cooling, and simplifies maintenance and troubleshooting.

A strategic placement of connectors and cable ties ensures a clean and organized internal layout.

Box builds are used in a wide range of products, from consumer electronics like smartphones and laptops to industrial equipment and medical devices.

Here are some uses and applications:

Electronics manufacturing

Box build assemblies are widely used in the production of consumer electronics such as smartphones, tablets, smartwatches, and other gadgets. Also in industrial electronics, they are used to house and protect complex electronic components.

Medical devices

Many medical devices, from diagnostic equipment to patient monitoring systems, are assembled as box builds. This ensures that the sensitive electronics are protected from external elements.

Telecommunications

In the telecommunications industry, box build assemblies are utilised to create communication equipment, network devices, and infrastructure components.

Automotive

Automotive control units, infotainment systems, and other electronic modules are often assembled as box builds for easy integration into the vehicles.

Networking equipment

Routers, switches, and other networking equipment are assembled as box build assemblies to ease the installation and maintenance.

Instrumentation, testing, and measurement devices

Scientific instruments and measurement devices often require a controlled environment. Box build assemblies provide a protective enclosure for the sensitive components and ensure exact results.

Aerospace and defence

In the aerospace and defence industries, box build assemblies are used for avionics systems, communication devices, and other electronic components in aircraft and defence systems.

Energy sector

Equipment used in the energy sector, such as power inverters, solar inverters, and control systems, are generally assembled as box builds.

As said, box build assembly can be as complex as needed.

An example of a box build is this assembly for a world-leading manufacturer of aerial cameras.

The assembly consists of various PCBA, components, cables, and the mechanical enclosure itself.

The box build is a key part of customers product, enabling the customer to capture high-quality images.

To ensure the product’s performance the box build is fully functional tested. It is a prime example of how important project management, a trustworthy network of suppliers and, and quality control is.

Another example is this box build for an optical product, or this assembly for a leading manufacturer of audiovisual solutions.

The process of box build assembly is complex. It consists of many steps from finding the appropriate suppliers of the many components, to assembling the box build, to testing and quality controlling the final product.

Because of these many steps and complex processes, there are many pitfalls in box build assembly. And just one mistake can elongate the manufacturing time significantly, meaning an increase in costs.

It can be difficult finding trustworthy supplier who can deliver the right and functioning component, at the right time, and in the right place. Especially if you are sourcing from a foreign country, having dependable suppliers are key to avoiding mistakes.

Lastly, quality control is very important. Because of the many possible mistakes that can appear throughout the assembly process, it is necessary to keep an eye out for any errors.

Certificates establish a framework for ensuring quality and production processes. Therefore it is important to consider which are relevant to your products.

Read this article for further explanation of the certificates.

1. ISO 9001:2015 (Quality Management System)

2. ISO 14001:2015 (Environmental Management System)

3. ISO 13485:2016 (Medical Devices - Quality Management Systems)

4. ISO 45001:2018 (Occupational Health and Safety Management System)

5. IPC-A-610 (Acceptability of Electronic Assemblies)

6. IPC J-STD-001 (Requirements for Soldered Electrical and Electronic Assemblies)

7. RoHS (Restriction of Hazardous Substances) Compliance

8. CE Marking (Conformité Européene)

9. UL Certification (Underwriters Laboratories)

10. REACH Compliance (Registration, Evaluation, Authorization, and Restriction of Chemicals)

11. WEEE Directive Compliance (Waste Electrical and Electronic Equipment)

12. Conflict-Free Minerals Certification

13. ISO/IEC 27001:2013 (Information Security Management System)

14. ISO 16949 (Quality Management System for Automotive Industry)

15. ESD (Electrostatic Discharge) Control Certification

16. TÜV SÜD Certification

17. FCC (Federal Communications Commission) Compliance

18. Nadcap (National Aerospace and Defence Contractors Accreditation Program)

19. Supplier Ethical Data Exchange (SEDEX) Certification

Box build assembly can be made by different kinds of companies. In general, there are two types of companies offering box build: Electronic manufacturing services (EMS) and contract manufacturers (CM).

Box build assembly can be made by different kinds of companies. In general, there are two types of companies offering box build: Electronic manufacturing services (EMS) and contract manufacturers (CM).

These companies have the expertise, infrastructure, and supply chain networks to efficiently manage the complexities of box build assembly across various industries. From concept to finished product, they offer expertise and resources that streamline the entire production process.

Because of the complexity of the box build assembly and the many pitfalls one can fall into, choosing an appropriate and trustworthy partnership is key. This will ensure a reliable process and decrease the number of problems in the assembly.

Looking at industry insight it becomes obvious that the market for box build assembly services is on the rise. In 2022 the global electronic manufacturing services market size was estimated to be $503.91 billion and is projected to grow significantly in the coming years.

By outsourcing the box build assembly to a specialised company, you will get access to an elaborate network of suppliers with speciality in the different components. The EMS or CM will already have devoted partnerships with the suppliers as well as experience in how to handle the communication.

Outsourcing a box build assembly offers several significant advantages for companies looking to streamline their operations and optimize their product development process.

|

Cost savings Outsourcing the assembly can lead to substantial cost savings. Setting up an in-house assembly line requires significant investment in infrastructure, equipment, training, and personnel. Your provider already has these resources in place, allowing you to avoid upfront expenses and ongoing maintenance costs.

|

|

Expertise and specialisation Your provider will be specialized in providing end-to-end manufacturing solutions, including box build assemblies. Their expertise ensures that your product is assembled and integrated efficiently, adhering to industry standards and best practices.

|

|

Focus on core competencies By outsourcing box build assembly, you can focus on your core competencies and company goals. Delegating assembly tasks to experts allows you and your team to concentrate on value-added activities that drive your business.

|

|

Scaleability Your box build provider is equipped to handle fluctuations in production volume, whether you need a small batch or a large-scale run. This scaleability ensures that your needs are met, regardless of market demand, without the need for constant adjustments to your own production capabilities.

|

|

Simpler logistics Instead of having 50 different component numbers in your system, you will just have the 1. By outsourcing your box build assembly, you will be able to obtain cost savings on individual parts, the overall subassemblies, as well as on logistics.

|

|

Quality assurance With the right provider you are ensured thorough quality control processes. This helps prevent defects and reduces the likelihood of costly recalls or rework.

|

|

Risk mitigation Partnering with a box build provider can help mitigate supply chain risks. They have experience in managing suppliers, handling issues, navigating potential disruptions, safeguarding your production timeline, and reducing exposure to unforeseen challenges. |

As you can see, delving into the field of box build assembly reveals both its intricate qualities and multifaceted challenges. The process, which coordinates the integration of various components into a cohesive whole, demands both precision and expertise.

That is why outsourcing the box build assembly often is a sensible choice.

Entrusting the assembly process to professionals not only frees up valuable internal resources. It but also allows you to profit from specialised knowledge and capabilities. The potential for using an existing trustworthy network, cost-efficiency, and the alleviation of logistical tasks underscore the advantages that outsourcing can offer.

As your business continues to evolve, embracing the potential of outsourcing can be a step towards achieving not only the optimal end product but also the streamlining of internal operations.

Want to learn how we can help you with your box build assembly? Reach out to our skilled team for a talk about your needs and requirements.

Other post that might interest you

- EA - Connect

- February 19, 2024

- EA - Connect

- January 26, 2024

- EA - Connect

- December 5, 2023