CUSTOMER STORY

Complex parts in mass production: 20 CNC machines running

Industry Medical and dental Location Denmark

The collaboration

A customer came to us with a complex project.

They were looking for a technically challenging alternative to their current setup. With production in the EU, they had the goal of reducing manufacturing costs.

Tight tolerances and high requirements

They needed an alternative surface treatment as the current contained chrome 6. Furthermore, the production must meet dental industry standards as well as the requirements from high-end clients.

That means flawless surfaces with no differentiation in color and surface shine.

From small to large production

Quickly the customer came with another request: A high production capacity. The EU plants simply could not meet the capacity needed.

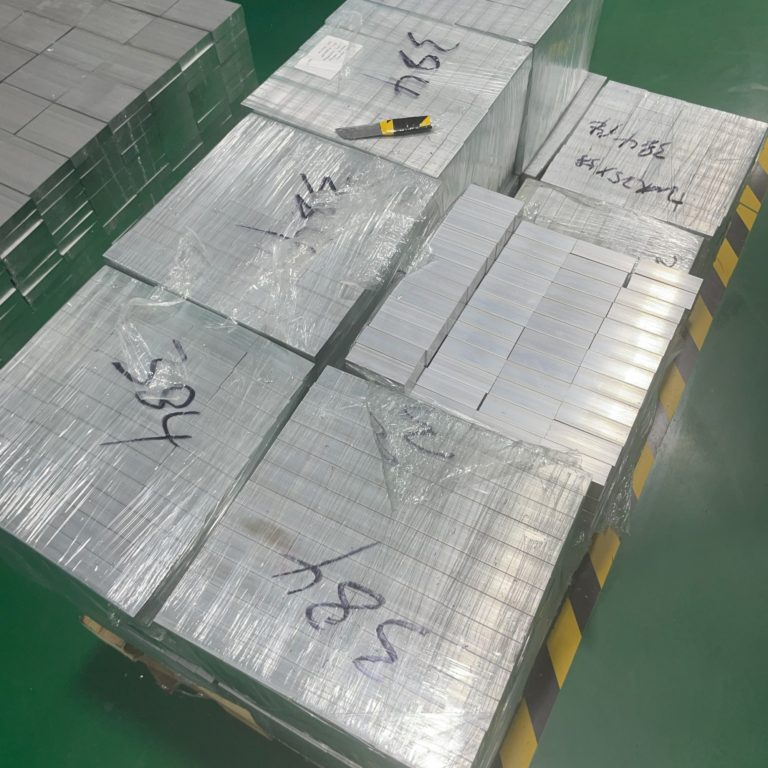

The request ended in mass production of the part. 20 CNC machines are simultaneously running and followed up with the surface treatment of the parts.

The company

The customer manufactures and delivers dental equipment and software to high-end dentists around the world. Delivering 3D scanners that are easy to use, the products support the dentist in their everyday work.

With a focus on perfection, innovation, and functionality the company is renowned for raising the bar of the industry.

The solution

- Materials: 6061-T6

- Solution: CNC machining, Anodizing (8-12 µm)

- Tolerance: ISO-22081